Expert Insights

Power grids are evolving rapidly, and substation automation is at the heart of this transformation. Many of us in the energy industry have seen old infrastructure struggle to keep up. Companies need better ways to handle renewable energy and keep grids stable. Substation automation isn’t just a technical upgrade—it’s a collaborative effort to build smarter systems that respond to faults in real time, optimize energy flow, and reduce downtime.

In this article, we’ll explore how substation automation systems work, from the sensors gathering critical data to the software orchestrating grid-wide decisions. If you want to understand the hidden systems that power homes and businesses every day, let’s look at how substation automation quietly makes it all possible.

What Is Substation Automation?

Substation automation uses technology to monitor and control electrical substations automatically. Substations are critical nodes in power grids, adjusting voltage levels and directing electricity flow. In the past, this required manual checks and mechanical relays.

Today, substation automation systems (SAS) replace these with smart sensors, controllers, and software. For instance, if a fault occurs, SAS can isolate it in milliseconds. This is much faster than human operators. SAS also integrates with grid automation systems, helping utilities manage energy flow across entire networks.

Demand for SAS is rising as grids face aging infrastructure and renewable energy integration. Solar and wind farms generate unpredictable power, requiring grids to adapt instantly—a challenge for older systems. Modern SAS uses communication standards like IEC 61850 to connect devices and enable remote control.

Industries like manufacturing and mining rely on SAS to prevent outages. Utilities remain the primary users, deploying SAS to reduce downtime and improve safety.

How Does Substation Automation Work?

Substation automation solutions use smart technology and layered systems to keep power grids stable. Let us look at how its structure, principles, and methods prevent outages and manage new energy demands.

Ø Structure of Substation Automation

Substation automation systems are built in layers to keep operations organized and efficient.

● Process Layer: This is where physical equipment operates. It includes sensors (to measure voltage, current, and temperature), circuit breakers, and transformers. Think of these as the hands and eyes of the system.

● Bay Layer: Here, devices like protective relays and controllers process data from the sensors. For example, a relay might decide to trip a breaker if it detects a dangerous overload.

● Station Layer: A central software collects data from all bays, displays real-time status to operators, and sends commands back down. We use this layer to coordinate actions across the entire substation.

Ø Basic Operating Principles

Substation automation works by turning data into instant decisions. Here’s how:

● Data Collection: Sensors in the process layer constantly monitor equipment. They track things like overheating transformers or sudden voltage drops.

● Local Decision-Making: Controllers in the bay layer analyze this data. If a fault is detected (e.g., a short circuit), they act immediately—like shutting off a breaker in milliseconds.

● Central Coordination: The station layer aggregates all data, showing operators the big picture. For instance, during a storm, we might reroute power to avoid outages.

Ø Basic Operating Methods

Modern substation automation relies on two main methods: standardized communication and remote control.

● Standardized Communication: Devices use protocols like IEC 61850 to share data seamlessly. A sensor in the field can warn a controller miles away, ensuring everyone “speaks the same language.”

● Remote Control: Operators adjust settings or reset equipment from a control room. We’ve used this to fix issues without sending crews to dangerous sites.

● Self-Testing & Predictions: Systems run automatic checks on equipment health. For example, they might flag a transformer nearing failure, allowing repairs before it breaks.

Substation automation relies on layered systems, instant data analysis, and remote control to keep power grids stable. We can use these tools to stop outages before they happen and meet today’s energy challenges.

Why Substation Automation Is Required?

We need substation automation products or solutions because traditional power grids can’t keep up with today’s energy demands. Old infrastructure, extreme weather, and fast-growing solar and wind power force grids to work faster and smarter. Substation automation turns outdated substations into systems that adapt and repair themselves.

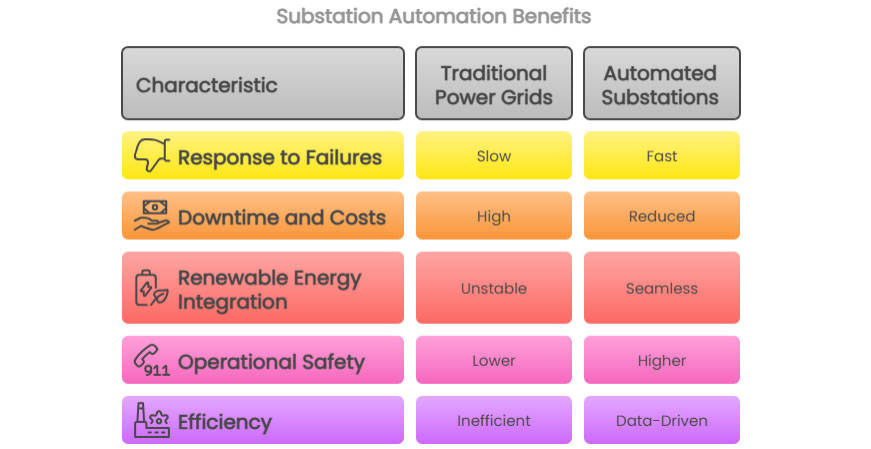

1. Faster Response to Failures

Automation finds problems like equipment overloads or short circuits immediately. For example, smart relays can identify a fault and isolate it in 10-20 milliseconds when human operators take 30 seconds or more. This quick action stops small problems from growing into major blackouts.

2. Reduced Downtime and Costs

By limiting damage during faults, automation cuts repair costs and downtime. Sensors predict equipment stress, allowing crews to fix problems before failures occur.

3. Seamless Renewable Energy Integration

Solar and wind power change with the weather. This creates unstable voltage. Automation fixes this by adjusting transformer settings and redirecting power instantly.

4. Safer Operations

Remote control reduces the need for workers to inspect high-voltage equipment physically. During wildfires or floods, operators can shut down substations from miles away. Thermal sensors also detect overheating equipment, preventing fires.

5. Data-Driven Efficiency

Automation systems collect terabytes of data daily. Machine learning analyzes this data to optimize energy flow, predict failures, and plan upgrades.

Without substation automation, grids can be inefficient, unreliable, and more expensive. We use these systems to fix current issues and to create infrastructure that works for future energy needs.

2025 Trends in the Substation Automation Integration Market

The global substation automation market is growing quickly. It was worth $47.76 billion in 2024 and will keep rising by 6.6% yearly until 2030. This growth happens because of three main issues: old power systems, higher electricity needs from cities and factories growing, and the push to use more solar and wind energy.

Utility companies now want systems that work reliably but can also adapt to changes. Because of this, there’s more demand for modern integration services.

One major trend is using IoT and AI to improve grid monitoring. Sensors and software check equipment health constantly. They find problems before outages happen. For example, AI can flag a transformer likely to fail within six months, allowing proactive repairs. Another trend is cybersecurity upgrades, as automated substations become targets for cyberattacks. Companies now add encryption and tools to spot unusual activity.

Leading Companies in Substation Automation Integration

1. ABB: A pioneer in digital substations, ABB combines hardware like protective relays with cloud-based software for grid-wide visibility.

2. Siemens: Focused on cybersecurity, Siemens builds secure communication networks and remote grid management tools.

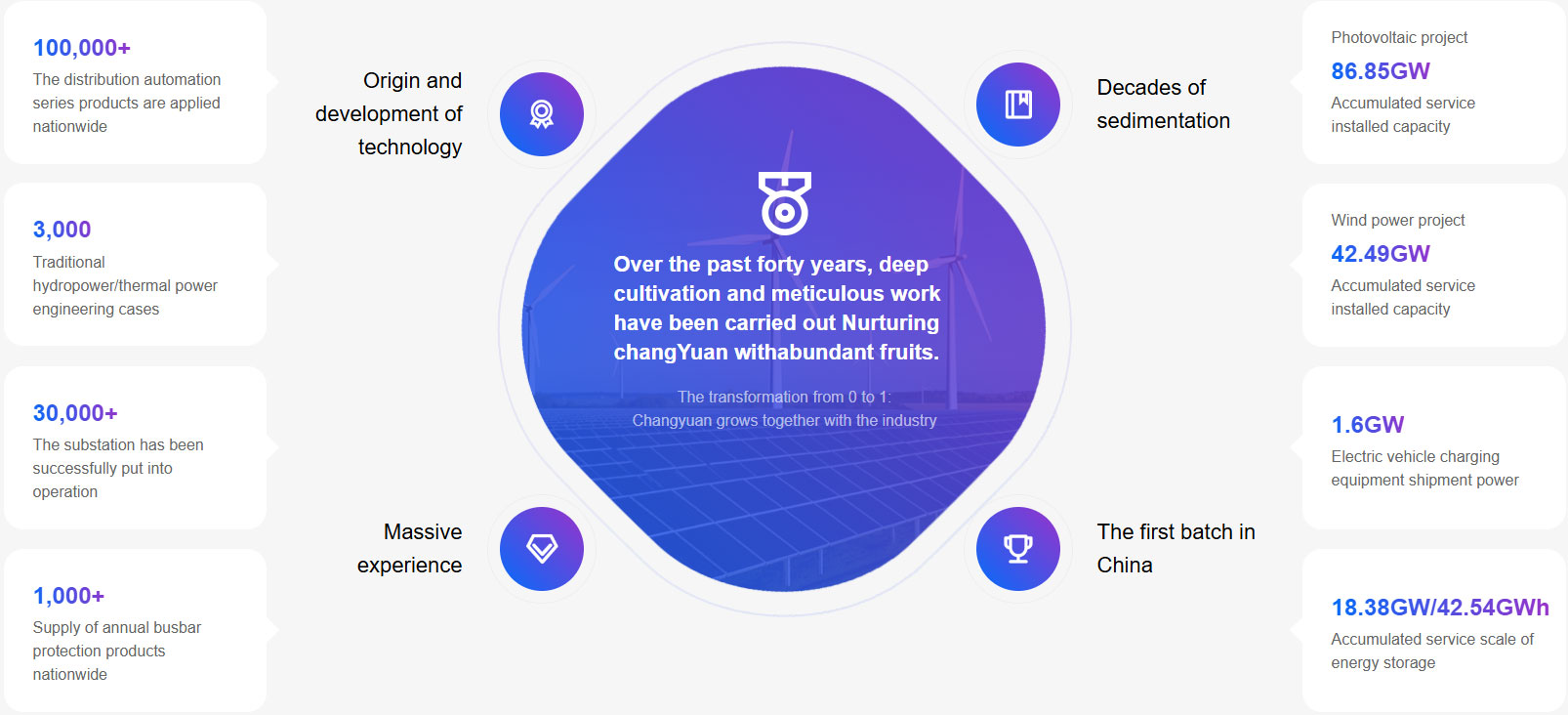

3. CYG: Emerging as a fast-growing innovator, CYG focuses on cost-effective digital solutions tailored to grid challenges.

4. Schneider Electric: Its EcoStruxure Grid platform helps utilities balance traditional and renewable energy sources.

5. Mitsubishi Electric: Known for high-voltage solutions and grid resilience technologies, Mitsubishi supports automation in earthquake-prone regions like Japan.

While North America and Europe dominate the market with robust infrastructure and early adoption of innovations, Asia-Pacific is rapidly catching up. Developing economies are investing heavily in energy infrastructure to meet soaring demand and decarbonization goals.

In this landscape, CYG EPBG (CYG Digital Energy and Power Business Group) has emerged as a key innovator. As a specialist in distribution automation and grid modernization, CYG EPBG develops integrated automation solutions that incorporate global standards (e.g., IEC 61850) while addressing local grid requirements.

For example, our smart distribution networks have been deployed in over 80 countries and regions worldwide, providing utilities with modular solutions to modernize aging infrastructure while ensuring backward compatibility.

With more than 20 overseas subsidiaries and 3177+ patents, CYG EPBG is advancing its vision to become "the world's leading brand in intelligent digital industrial and power systems" through localized technological innovation and adaptive grid solutions. We continue to expand our international presence, delivering cost-effective and adaptive solutions tailored to diverse grid modernization needs in emerging markets.

Conclusion

Substation automation turns traditional power systems into smart networks using basic sensors and real-time data. It automates monitoring, control, and problem detection, which reduces manual work and makes grids more reliable.

For businesses, this leads to fewer power outages, cheaper maintenance, and better energy distribution. These benefits matter most for renewable energy projects and industries needing stable power. The advantages are easy to see: predictive maintenance slashes downtime, and data tools help use resources smarter.

At CYG EPBG, we help companies make this change. Whether you’re updating old systems or building new automation plans, we work with you. If you’re thinking about how automation could simplify your operations or have questions about getting started, contact us. We’ll find solutions that fit your needs. Better grids begin with practical choices.